Blueproof Fire house demonstration

You can send out reports. You can send out data and videos. But often, especially when something’s new and innovative (as Blueproof undoubtedly is), people want to see things with their own eyes. And so it was, on a chilly day at the end of November, that Team Blueproof were at The Dukeries – Nottingham Fire and Rescue’s Service Development Centre in Broughton Notts to give a demonstration of Blueproof to invited guests in the Fire house.

There’s a three-story building there, with stairs, so it’s perfect for a fire test. You get to see what happens on the ground floor AND both on the stairs and up the stairs. It’s an impressive centre with thermo couplings recording temperatures throughout; they even have a control room at the rear where you can see temperatures on a monitor.

The objective was to demonstrate the operation, the temperature effects on the upper floors, stairwell and the elimination of flash over (something firemen dread). If you want the official science bit – the process and procedure were based on test methods given in ISO TC 021/SC 05 N634 Dated: 14/06/2013 for sidewall mounted sprinklers.

With the help of Watch Manager, Simon Lilley and his great team we ran two burns. The first was a straightforward “benchmark”. No radiator, no Blueproof. Just “let’s light a fire and see what happens”. Then we ran a second demo where we set up a radiator by the pallets so we could demonstrate the difference.

Both burns used pallets as the fuel (about the same as a three – seater settee). Ignition was via a simple burner from a small gas bottle and we used newspaper as kindling. The radiator was just an ordinary domestic one. The pressure in the radiator started at 2.5 bar but, as a result of the heat from the fire, at the end it was around 9 bar.

The invited guests arrived after the benchmark demo, so we told them all the details and the temperatures that the fire caused. We then re-iterated what Blueproof does and explained the mechanics of the demo.

Everyone crowded round the main door to watch the fire being lit. That door was then shut – with a fireman wearing breathing apparatus remaining inside. He had a thermal imaging camera and was going to get footage of whatever happened. The crowd migrated to the control room to watch the monitors.

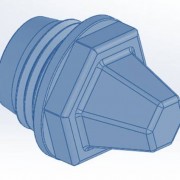

We knew our device would “fail open” (as it’s called in technical terms) that is. it would soften, and one facet would burst open allowing water out.

During our numerous, previous laboratory experiments we’d seen the behaviour at the surface of the device. But being able to watch images on a thermal camera was an eye opener even for us. What it revealed was that the spray pattern formation at the surface of the device was in response to changes in the dynamics of the fire. The higher the temperature, the higher the discharge of water directed at the fire in response.

With the first discharge stream halted the fire’s spread towards the device. The second stream blasted the ceiling as the fire flared upwards. The third stream stopped the fire moving towards the right and the fourth stream stopped the fire moving towards the left.

So not only did the device curtail the movement of the fire during the suppression but it also automatically responded to any further growth. This was not area coverage but targeted coverage directly into the moving heart of the fire.

The temperature levels reached during the benchmark were, as expected, not reached during the second “Blueproof” demo. In the benchmark the peak temperature was 350 degrees C at waist height – and much higher at the ceiling (around 800 degrees) and lower at the floor (around 80-100). But Blueproof’s demo saw a peak (at waist height) of around 290 degrees.

This was particularly important in the stairwell where a significant fall was recorded during the Blueproof demonstration. The door to the stairs had been deliberately left open to allow the vent gases to migrate to the upper floors.

It had been demonstrated at Governors Island* during live burn experiments that very little water had a massive effect on a fire. However this is the first time it has been proven that the application of very little water directed onto a rising fire holds back its growth and has an even greater effect.

With the device fitted during the demonstration the vented smoke colour on exit from the building was observed to change from black to white as the moisture became entrained in the vent gases and they became saturated. This makes the deadly toxic black smoke produced from a fire, much safer for any survivors caught in the smoke to breathe.

When the door to the fire burn area was opened, a significant spike in the temperature occurred in the stair well as the oxygen entered the room. This shows that any trapped occupants on the upper levels would be subject to a rapid temperature rise. Rescue crews would also be subjected to an increase in temperature of the ceiling gases once oxygen is allowed to enter the fire area.

Although the demonstration was undertaken with sufficient fuel to cause Flashover, this didn’t occur as the ceiling gases had become saturated with water. Preventing the deadly event.

The discharge pattern from the Blueproof device had become a fully developed array of continuous targeted streams of water and spray.

This was all captured on video by an experienced ex-BBC cameraman.

You can see the video here on youtube

Blueproof is also available on Amazon.co.uk at a low introductory cost of £20. Buy now and get the best sprinkler system on the market at a fraction of the cost of other conventional systems.

Leave a Reply

Want to join the discussion?Feel free to contribute!